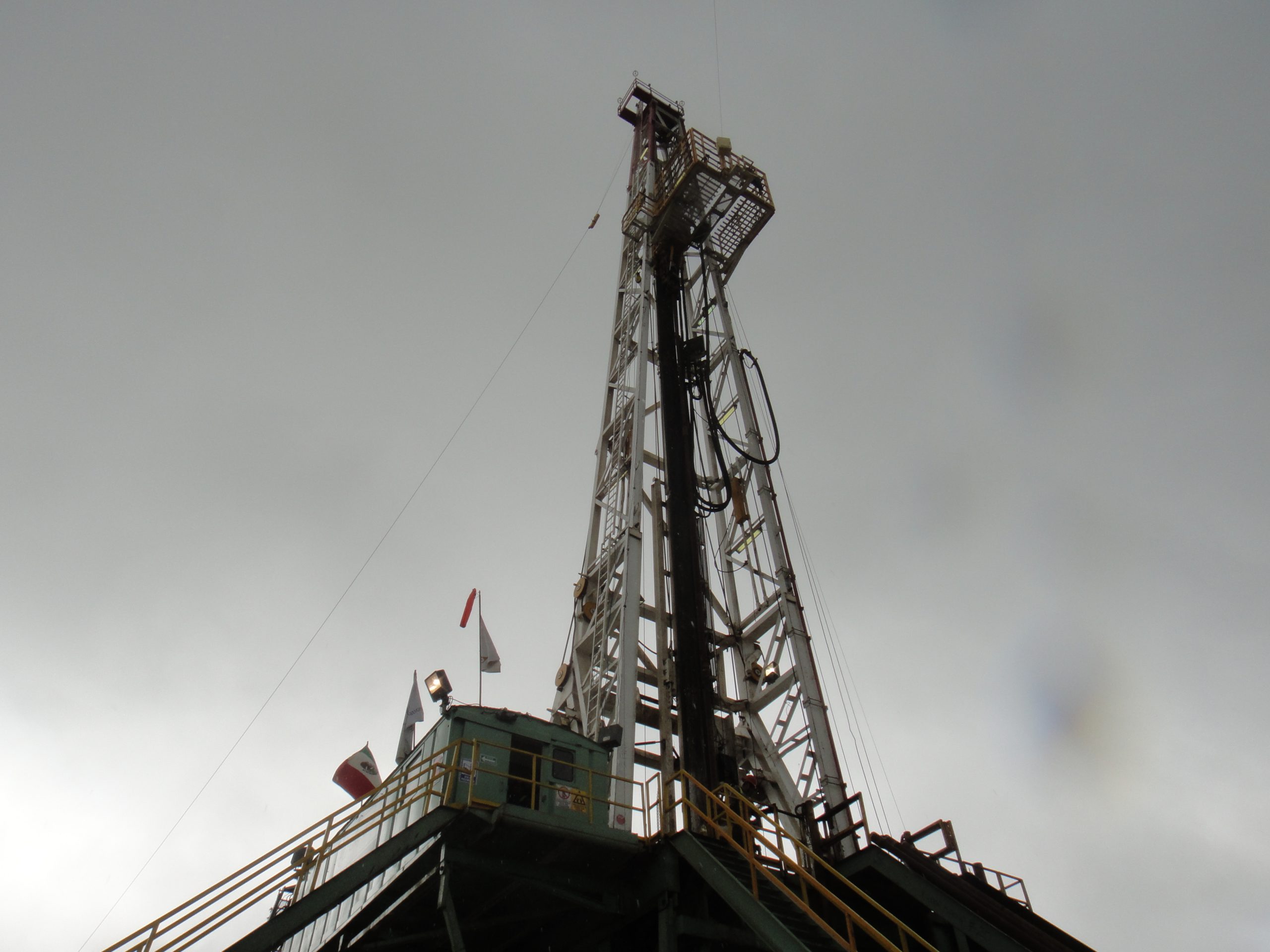

Lean Drilling™ – Multiple Projects

Project Name: Multiple Drilling Operations Globally

Client: Multiple Companies (Majors, Independents and Turnkey Drilling Contractor).

Project Dates: 1995 – Present

Results include: Step change 50% time reduction, 30% cost reduction, best-in-class global benchmarks.

Lean Drilling™ is a Trademark of DE WARDT AND COMPANY.

John de Wardt’s unique background as an operator, drilling contractor and service company provided the basis on which the attributes of Lean Manufacturing were translated to drilling and completion operations in a bespoke program.

Lump Sum Turnkey, Saudi Arabia – 26% reduction step change in well drilling time across 4 land rigs drilling Lump Sum Turnkey wells in South Ghawar field. Client continued to reduce drilling times. Challenging wells with hard rock and major losses.

Concept Development, JV Mexico – Economically challenging land development project applied Lean Drilling™ in conceptual phase. Result was a 60% reduction in well costs and 20 % increase in estimated well productivity with massively reduce well OPEX (2-year interventions expanded to 10 or more years).

Concept Development, Colombia – Uneconomic field flank prospects were made economic in terms of FDP based on completely new concept using light weight drilling rigs and low-cost expendable wells.

Extremely Mature Field, Romania – Results achieved an impressive 40% reduction in drilling and completion time for the wells which faced challenges from soft formations that are difficult to build inclination to intermittent depleted sands which create a complex pore and frac gradient regime with a narrow mud weight window.

Development Drilling Independent Operator, Nigeria – Applied Lean Drilling™ and established Well Delivery Process resulting in Jack Up drilling operation moving from poor performance to best-in-class West Africa on industry benchmarking (Rushmore Review). NPT reduced from 30% to 7%. Production in one field increased by 50% per well.

Abandonment Offshore Sub-Sea Wells, Norway – Load out of semi during national strike, abandonment of three separately located subsea wells. Achieved effective 45% less duration than conventional planning / execution.

Field Extension and Abandonment, Norway – Deferred shut in of producing field using a contracted jack up rig as the producing platform against a firm rig termination date. Budget for the shut in of 7 wells was 98 days; a Technical limit of 50 days was established. Actual shut in took 69 days, a time reduction of 30% saving unit rental costs and extending revenue.

Appraisal Well, GOM, USA – Deep Water Appraisal well (4,600 ft. water depth) TD 21,330 ft. using semi-submersible rig in a record best-in-class performance of 21 days per 10,000 ft. This ‘S’ shaped well drilled through a thick salt section with a pressure regression and tar below.

Multiple Projects, Major, Norway – drilling improved from lower third quartile to upper first quartile ranking based on days per 10,000 ft.

Major Operator, Norway – A 4400 meters development well with an 1100 meters horizontal section was drilled at double the overall field plateau performance, using a type 2 semi-submersible unit in some 350 meters of water. The intelligent completion installation was performed in half the planned duration. Client stated, “the result was ‘even better than the Technical Limit Curve for this well’. This result realized capital cost savings of (33%) US$ 7.5 million.

Offshore Exploration, Major, Norway – well drilled in 20 days per 10,000 ft.; top ranked across N Sea on days per 10 K ft. AFE 46 days, Stretch Target 29 days, Actual 27 days with full data acquisition.

THE CHALLENGE

Drilling operations contracts are typically misaligned with performance objectives of all parties targeting different outcomes. Organizing an effective integrated team of various different departments and skill sets with their multitude of suppliers is a very challenging task that few have accomplished.

THE METHOD

Organizing an integrated team of various siloed departments with different skill sets and their multitude of suppliers requires our bespoke program. Our development of a customer owned delivery-based organization driven by personal recognition delivers huge performance increase. We facilitate the re-alignment of organization to an architecture of experts in the right place.

CLIENT TESTIMONIAL

John de Wardt and his concept of Lean Drilling™ has been used by Statoil on a number of wells with the objective to increase efficiency and reduce cost in Statoil’s drilling and well operations. The systematic approach used offers great advantages in establishing ambitious goals and defining risks in a costly offshore drilling and well operations project. Statoil has seen significant improvements in results and has adopted the principles in our planning and operations efforts.

Mads Grinrod, VP Drilling and Wells (Retired) Statoil.

John delivers performance in upstream oil and gas. Uniquely; he pulls together subsurface, drilling, production and facilities departments while incorporating all suppliers into an aligned team regardless of past experiences and divisions. In West Africa, John supported us to deliver best in class performance on industry benchmarks.

Yanis Korakakis, COO Addax Nigeria (former).

I worked with John on multiple projects. His deep expertise in upstream oil and gas had brought significant bankable impact to those projects. We saw both increase in revenue and reduction in cost. John’s methodology setting a stretch goal and providing tools to achieve them are proven to be effective. A leadership team of an O&G company that wants a quality transformation program should involve John.

Sanzhar Zharkeshov, CEng; Chairman of the Management Board at QazaqGaz – the National Gas Company of Kazakhstan, former McKinsey

When we drilled a record breaking exploration well in Norway in 1998 (Barden), John worked with the team to implement his Lean Drilling™ method. One of the offshore drilling supervisors commented that the “operation felt quite weird”. The well seemed to be progressing at breakneck speed and yet everybody on the rig appeared to be going about their tasks in slow motion. Such was the result of very detailed planning and highly disciplined execution.

Dr. John Thorogood, Drilling Global Consultant; formerly BP PM on Exploration Wells